The advantages of 3D printing in manufacturing

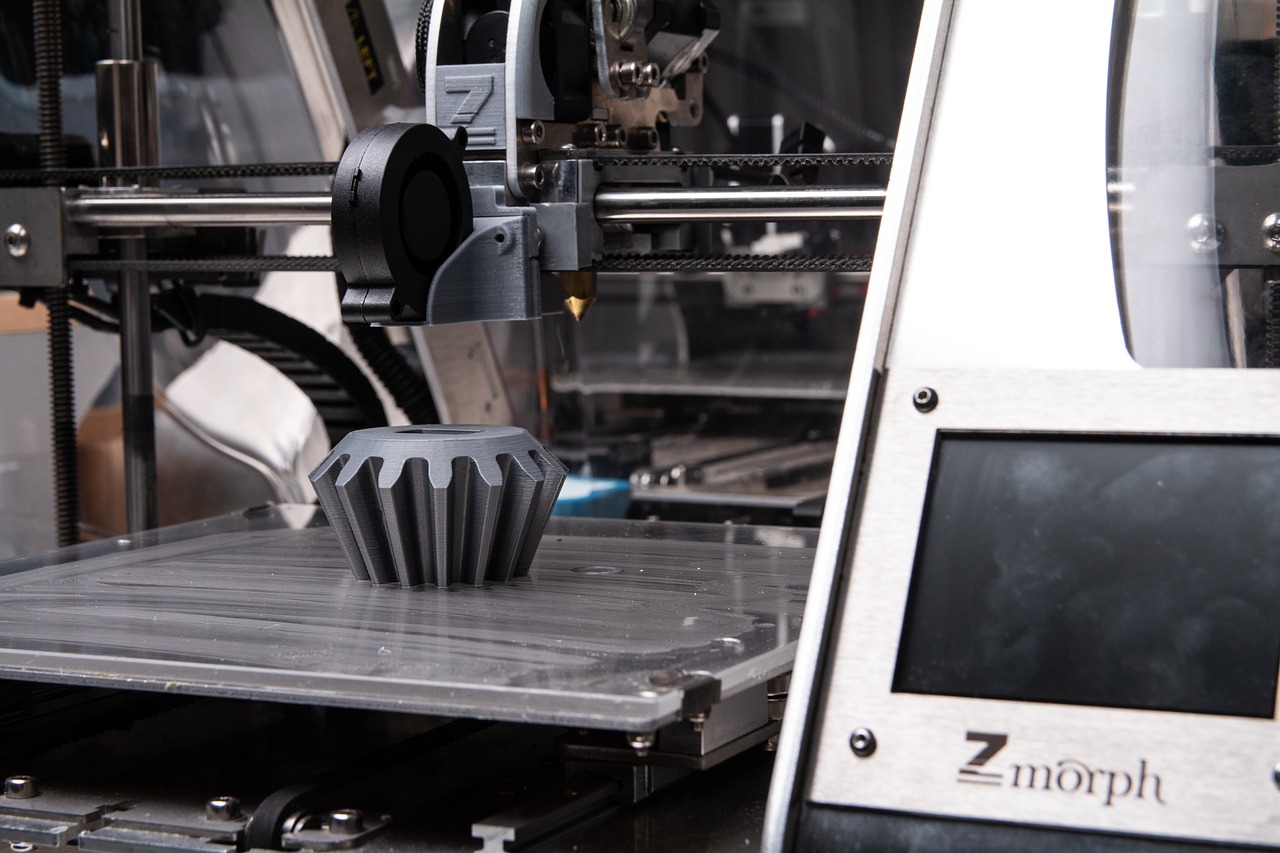

3D printing is the process of creating three-dimensional objects and products via either joining or hardening materials & putting them in an order layer by layer. The whole process is completed under the computer controls. It is also known as Additive Manufacturing and set its pillars in the field of manufacturing in the recent couple of years. 3D printing is commonly used by businesses and hobbyists. It is being updated by the latest high-quality 3D printers each year to help people create perfect products. It helps designers and manufacturing professionals make better decisions in choosing the better and most effective manufacturing processes to deliver their customers great products.

Sponsored content

More and more companies have contained 3D printing in their manufacturing processes and others are planning to replace traditional manufacturing with advanced 3D printing.

Below are the noteworthy advantages of 3D printing technology in manufacturing and how it can help businesses improve their manufacturing processes for better business growth.

Faster Production

The process of creating products or designs with 3D printing is much faster than conventional manufacturing methods like injection molds and subtractive production. As both a supercar and a horse cart reach their destinations, but the time difference is huge.

The 3D printing process from creating and prototypes to a final product is quick and efficient.

As manufacturing companies like RapidDirect use advanced 3D printers, these are better able to create product prototypes and final products faster than ever before. Faster production means the business has more time to repeat the prototype and find the appropriate product market before its competitors. This technology just takes hours to get products produced but traditional manufacturing methods take days instead.

Easily Accessible

It is very easy to learn 3D printing technology and businesses can integrate it into their manufacturing processes just in a matter of days. Due to the increasing 3D printing interests, experts have introduced easy to use hardware and software for both individuals and companies so they can take advantages of this manufacturing technology without facing troubles and spending a lot of time.

Better Quality Products

Businesses are more likely to create imperfect designs and poor-quality product prototypes too.

They are not assured to provide 100% quality products when using manufacturing methods like injection molds. On another hand, 3D printing offers step by step project assembling that enables you to create perfect designs and better-quality products ultimately.

Risk Mitigation

A faulty product prototype can cost designers or companies a lot of money and time as well. Even sometimes they may need to go through the massive financial impacts in terms of making minor changes in the fabrication or mold method. Instead, verifying a design made via 3D printing eliminates the financial and other risks associated with the manufacturing process. Companies can check their designs before investing in expensive manufacturing machines and equipment. It helps them build high-quality products without experiencing any risks or error rates.

Affordable

One of the major advantages of 3D printing in manufacturing is that it is affordable as it comes with a low labor cost.

Labor cost is one of the most vital elements in deciding the budget to be used in creating a manufacturing framework. Conventional manufacturing can cause higher labor costs as they required highly skilled and experienced operators to operate manufacturing equipment and machines. In 3D printing, all you need a printer and software to get started the process. Even a single button press starts the automated process to get a design created quickly.

Limitless Shapes and Geometry

As traditional manufacturing methods rely on cutting technologies and molds to create the desired shape, creating geometrically complex shapes can be difficult, time taking and expensive with this outdated manufacturing technology. But 3D printing can do this with ease as it comes with a lot of shapes and geometry to help you create complex shapes and designs within minutes.

Flexibility

Flexibility is another significant advantage of 3D printing in manufacturing as any 3D printer can create almost any design or prototype that fits within its volume range. Traditional manufacturing requires a new tool, die or jig when it comes to make a new part design or make changes in design. But 3D printing the desired design is fed into the software needed support is added and finally printed in a short span of time without changing hardware or manufacturing equipment.